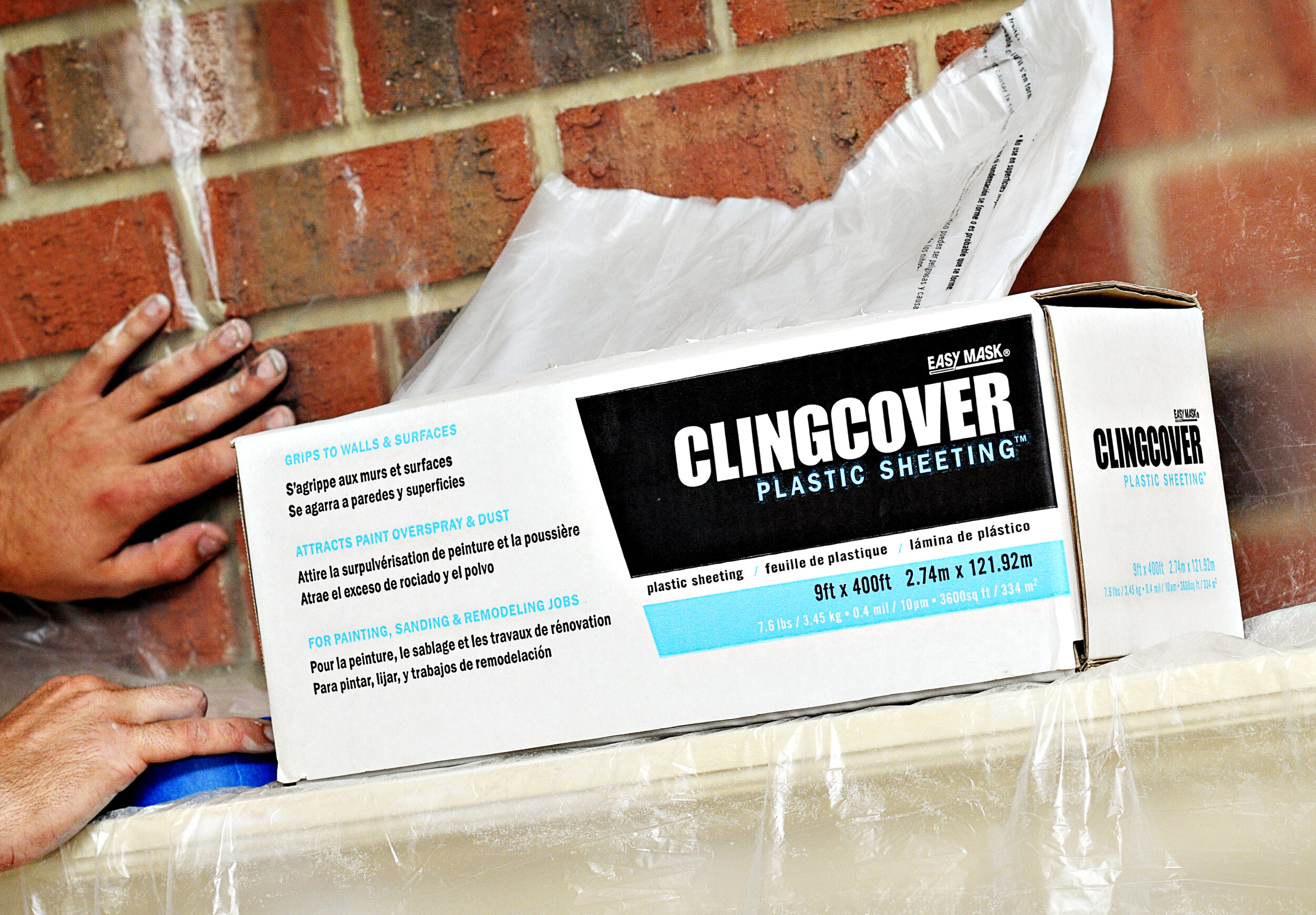

trimaco package design

Trimaco is a manufacturer and distributor of paint and worksite protection products - selling both Trimaco brand products and private label designs into Lowes, The Home Depot, Walmart, Sherwin Williams, and more. Around the time I began working at Trimaco, new standards for selling products into Canada required distributors to add French to all packaging. I led the team which redesigned all packaged goods from bilingual to trilingual. Trimaco rebranded every product throughout the two-year process.

Applying artwork to various substrates requires different techniques. Printing on corrugate (above) is very imprecise. A significant overlap between separations is needed to ensure full ink coverage. Printing on plastics comes with its challenges and also its affordances. Below, the areas in brown represent the paper tape coming through a transparent portion of the packaging. A designer must break a cardinal typographic rule with both types of packaging by applying a stroke around the text. The thicker line weight prevents the outer ink from filling in the lettering on the packaging, ensuring the wording remains legible. With each packaging project, the design team created both miniature and full-size prototypes to ensure proper fit. With some dielines, areas of the packaging, which appear flat on the screen, need to be placed upsidedown.

The experience I gained in package design included overseeing the offset printing process from creating separations, selecting Pantone colors, doing print visits to check for accuracy, working with dielines, reviewing physical and digital proofs from both domestic and international printers, and creating working prototypes. It also included a significant amount of branding work and some copywriting, when needed, to update product taglines and descriptions if the past material wasn’t up to par. Store visits allowed the creative team to see how product packaging would work on store shelves, and merchandising was an essential part of the packaging process.